Adhesion Strength Testing & Bond Strength Determination – Precise Analysis for Maximum Adhesion

Adhesion strength testing and bond strength determination are essential methods for evaluating the performance of adhesives, coatings, and composite materials. They provide valuable insights into the durability, reliability, and load-bearing capacity of materials – a crucial factor for quality assurance and product development.

Adhesion Strength Testing: Measuring the Load Capacity of Adhesives

Adhesion strength testing determines the force required to separate an adhesive bond. This provides critical information on the mechanical resistance and long-term reliability of the connection.

Bond Strength Determination: Ensuring Coating Adhesion

Bond strength testing evaluates how well a coating or material adheres to a surface. This is particularly important in industries such as automotive, aerospace, and medical technology, where strong adhesion is essential for safety and performance.

High-Precision Analysis with CAT Technology

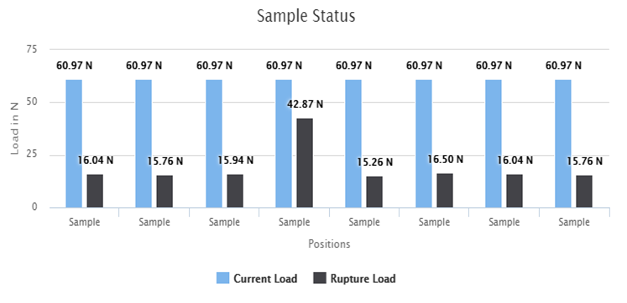

For detailed analysis of adhesive bonds and composite materials, we utilize Centrifugal Adhesion Testing (CAT) technology. By applying increasing centrifugal forces, the tensile and shear strength can be precisely determined as absolute physical values in N/mm² (MPa).

Additionally, we offer fatigue testing under varying loads and temperatures to ensure the long-term durability of your materials.

Versatile Applications for Various Materials

Our testing methods are suitable across multiple industries and can be applied to:

✅ Adhesive bonds (Substrate I / Adhesive / Substrate II)

✅ Coatings & paints

✅ Foils & films

✅ Composite materialsConclusion: Maximum Adhesion for the Highest Quality Standards

With our innovative testing methods, we ensure maximum safety and reliability for your materials. Contact us for a tailored analysis and optimize the performance of your adhesive and coating systems!

Auftragsanalytik

Auftragsentwicklung

Referenzmaterialien